-

RealWheel motor

- Gravity wheel from Alain Graillat

- Gravity wheel from Maillardet

- RealWheel motor

- Engine with autoadaptable cons reaction not equal to action

- Oscillateur mécanique à double oscillation

- Alternatif à effet centrifuge

- Robert Cook's inertial propulsion engine

- Angular force generator

- Machine propulsive à masses rotatives

- Edition

-

RealWheel motor

Creation date: 25th of March. 2010 - Updated on 2012.11.02, 2014.03.30, 2015.07.01

Download the French translation - Télécharger la version Française

Mechanical converter motor from static energy into kinetic energy - COP infinite - Nationality of inventor : French

The inventor

Graduated from a high engineer school, the inventor has held various technical and commercial positions in a large multinational group. His confirmed passion for energy has logically led the inventor to study machines more environmentally sound and capable to produce energy in unlimited quantities, at a price affordable for all.

Description of invention

Thanks to a subtle and ingenious mechanism, the motor converts a static force, whose average power is zero over a complete cycle of rotation, in a torque at constant rotation speed (if the motor is coupled to a resistive load) and producing a net power release.

Because the engine is placed continously in a unstable state, it requires no energy for its starting and during continous stable operation. The motor converts simply the works of the internal forces in a net energy recoverable at the outlet of the machine.

This motor, as demonstrated by theory, cleary violates Newton 3rd law globally (reaction is equal and opposite to action), but not of course locally between two adjacent parts.

The torque variation (positive or negative torque) requires a very low amount of energy and can be obtained :

- either by changing the intensity of the applied static force,

- or by doing vary the lever arm length (positive or negative value). At startup, the lever arm has zero length. A positive value will cause the rotation in one direction, while a negative value will cause a rotation in opposite direction.

The motor includes its own system of continous variation of torque and then of speed.

The engine's 'Coefficient of Performance' is infinite.

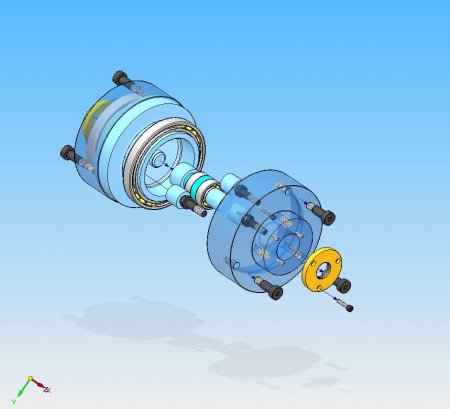

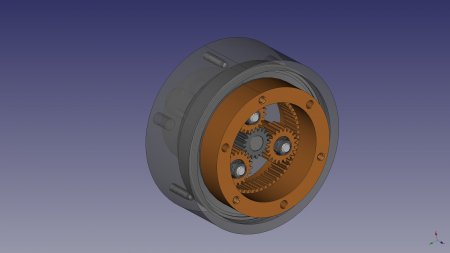

Exploded view of epicyclic gear mechanism

Animation of the epicyclic gear mechanism

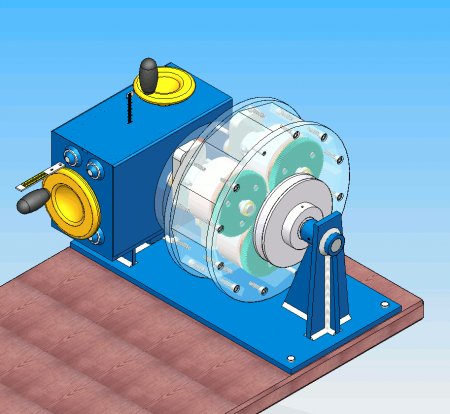

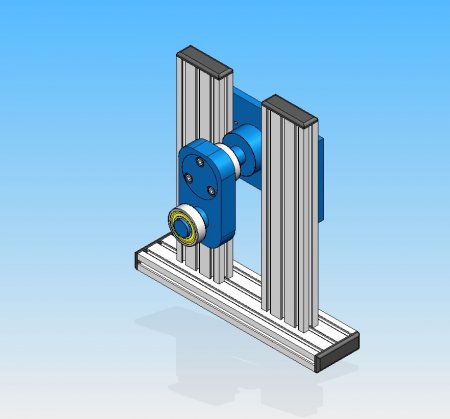

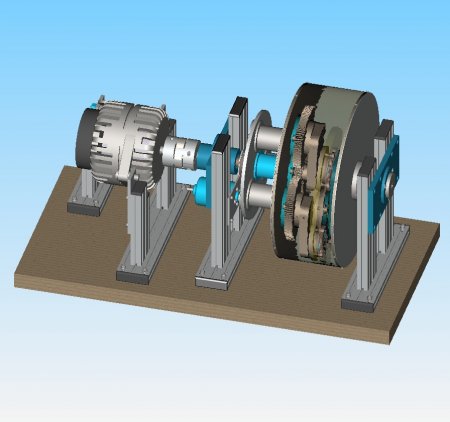

Layout view of first prototype

Proof of operation

The theoretical study, achieved in June 2008 and translated in English in May 2009, includes thirty two pages with colored schemes of transmitted stresses throughout the driveline. The study shows that the action torseur of external forces is not equal to reaction torseur leading the engine to develop an infinite COP. The calculation method of various mechanical losses is indicated in this study.

Excerpt from theoretical study of motor RealWheel ( proof by calculation of Newton 3rd law violation ).

It remains to build the first test prototype engine weighing about 10 kg.

Characteristic parameters of motor

The values of sustainable development parameters are the following :

- REN=100% (no fossil energy used during operation of the motor),

- EFF=92% (mechanical efficiency of a rotating machine at speed of 3000 rpm. Mechanical losses are those of gears and bearings),

- COP = infinite (no energy brought by the operator at startup and during continous stable operation. Reduced energy expenditure is necessary, however, in the case where one does vary the applied torque),

- MDP= 2 T/MW (the ratio depends on complexity of the machine : symmetrical or asymmetrical design, presence or absence of an inlet reducer),

- DUR=infinite (a machine consisting of gears and bearings does not build up over time irreversible wears. All wear parts are replaced within the framework of the machine's scheduled maintenance),

- GGO=0 (no fossil fuel is consumed during operation of the machine),

- GGM=4,11 x 10-6 TCO² /MWh (negligible emission of greenhouse gases corresponding to CO2 emissions for manufacturing material, ratio weighted for a 50 years operating lifetime),

- HEH=0 (no hazardous or radioactive wastes are generated during manufacture or operation of the motor),

- MRF=100% (all the materials used fro manufacturing the motor are recyclable: steels, lubricants,....),

- EIR=0 (one can consider that the motor has a zero environmental footprint: very low production of CO2).

The engine has no negative environmental footprint.

Sponsoring

The following companies have sponsored the supply of standardized pieces:

- SKF France : supply of 35 ball and thrust bearings,

- Titanox France : supply of 25 retaining rings from Smalley trade mark.

Financing of project

The project will require investors after manufacture of the prototype for filling up a national and worldwide patent (€ 400,000), for creating a company in charge of engineering, manufacture and sales, but also for commercializing patent licences in several fields of activity (several millions of euros).

Progress of test model manufacture

The manufacture drawings were achieved on 10th of September.2011. The purchasing of materials and standardized pieces already begun, as well as the first machinings.

Assembly of the lever arm output shaft

with its spacer and its ball bearing

Detail of the various parts

The prototype model should be completed by the end of December 2014.

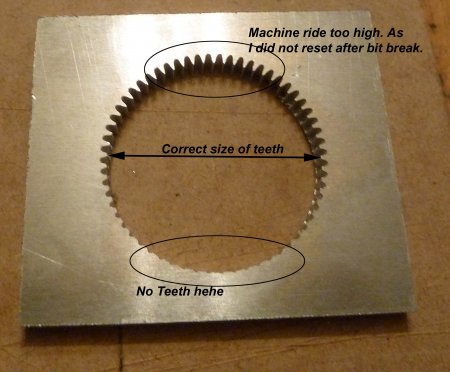

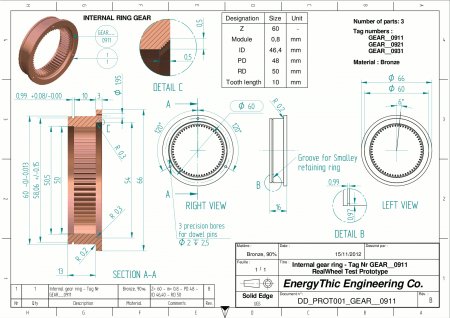

Machining test of the inner gear

with a CNC DUDEZ Desktop machine

Detail manufacture drawing of inner gear

Piece redesigned for fitting with capabilities of CNC DUDEZ desktop machineJuly 2015 : further to impossibility to machine the internal gear of epicyclic trains by means of conventional ways, 3D metal printing should be used. New drawings are being issued with FREECAD beta version software. Previous used software is now obsolescent. The number of teeth were modified in order to comply with "bean rule".

The engineering works of the second version of the motor are almost completed (10th of March.2013). The drawing herebelow figures out the pivot fix support assembly. This new motor is able to deliver a self-adaptable torque according to the load required by the generator.

Layout view of second prototype

Detail of fix pivot

Layout view of second prototype

The mechanical decoupling between inlet and outlet allows to breach Newton's third lawPublic announcement

The public announcement will be carried out after applying patent before French INPI.

- either by changing the intensity of the applied static force,